during the demanding earth of drilling operations, performance and security are paramount. although Considerably interest is provided to your Main drilling course of action, the supporting devices, like mud mixing hoppers, usually goes unnoticed right until an issue arises. And what’s one of the most prevalent, but perhaps highly-priced, problems with mud mixing hoppers? Leaks. A seemingly slight drip can swiftly escalate into a big lack of valuable drilling fluid, generate hazardous Operating disorders, result in environmental issues, and ultimately, affect your bottom line. picking out the appropriate mud mixing hopper from the trustworthy mud mixing hopper maker is more than just a invest in; It truly is an investment decision in operational integrity. This is exactly why comprehending the nuances of leak prevention and excellent sealing technologies is crucial for any drilling Procedure. this post delves in to the crucial areas of developing, operating, and maintaining leak-evidence mud mixing hoppers, giving insights to reduce hazards and improve performance. For operators contemplating machines sourcing, evaluating choices from a China mud mixing hopper company demands cautious thought of those extremely factors.

Table of contents:

Structural Seal structure: The Foundation of Leak avoidance

Operational Procedures for Leakage Management

Leak Detection and Response Systems

Maintenance and cleansing tactics

substance Compatibility: A essential to extensive-time period Integrity

Handling Intense circumstances

Structural Seal style: the muse of Leak avoidance

The fundamental integrity of the mud mixing hopper hinges around the robustness of its structural seal structure. This goes beyond just bolting parts alongside one another; it needs a deep knowledge of supplies science, fluid dynamics, and mechanical engineering rules.

Dynamic Seals (Rotating parts): Mixing hoppers generally include rotating shafts for successful mud Mixing. The sealing mechanism in which these shafts penetrate the hopper wall is a crucial place of potential leakage. Two Major technologies are employed:

Mechanical Seals: These seals supply outstanding leak avoidance in comparison to traditional packing. They comprise two highly polished faces, just one stationary and one rotating, held jointly by a spring mechanism. The near Get in touch with in between these faces creates a tight barrier versus fluid escape. the selection of supplies to the seal faces is crucial; options contain silicon carbide, tungsten carbide, and numerous grades of chrome steel, with regards to the abrasive character from the drilling mud along with the opportunity for chemical attack. Mechanical seals desire specific installation and alignment.

Packing Seals: Packing seals use compressible components, which include graphite-impregnated PTFE (Teflon), wrapped round the rotating shaft and compressed by a gland. whilst easier and cheaper than mechanical seals, packing seals are prone to use and involve periodic adjustment to take care of a powerful seal. They're also much more more likely to leak, specifically when managing abrasive mud formulations.

When picking out among mechanical seals and packing seals, contemplate the following:

Mud composition: Abrasive fluids need much more strong and resistant seals.

functioning strain: large force applications gain from mechanical seals.

routine maintenance requirements: Packing seals need standard adjustment, Whilst mechanical seals are more self-retaining.

Static Seals (Flanges and Connections): The points exactly where different sections on the hopper are joined collectively, including flanges and pipe connections, also are susceptible to leaks. The choice of gasket material is paramount.

Gasket resources: typical gasket elements include things like:

Elastomers (e.g., Nitrile Rubber, Viton): These give fantastic sealing Homes and resistance to a range of chemicals, but their temperature and force limitations have to be thoroughly considered. Viton features remarkable chemical resistance in comparison with nitrile.

Compressed Fiber: These gaskets are constructed from cellulose or synthetic fibers bonded with rubber or resin. They offer superior resistance to pressure and temperature but are susceptible to chemical assault.

PTFE (Teflon): PTFE gaskets present superb chemical resistance and a large temperature vary, but These are somewhat soft and can be susceptible to cold movement (creep) below significant strain.

Spiral-Wound Gaskets: These gaskets include alternating layers of metal (normally chrome steel) as well as a filler material (such as PTFE or graphite). They provide superb sealing effectiveness underneath significant strain and temperature and present excellent resilience to deformation.

the choice of the appropriate gasket materials is dependent upon the chemical composition with the drilling mud, the operating temperature and pressure, plus the flange surface area end. appropriate torque application is essential to be sure a good and reliable seal.

Redundancy: employing double sealing systems delivers an added layer of protection. one example is, a Most important mechanical seal backed up by a secondary lip seal. This redundancy makes sure that if the primary seal fails, the secondary seal will reduce leakage right up until maintenance is often executed.

Operational Procedures for Leakage Handle

Even the best-created mud mixing hopper can leak if operated improperly. pursuing established protocols and employing finest tactics are essential.

stress administration: Fluctuations in pressure throughout the hopper can tension the seals and enhance the probability of leakage. using pressure reduction valves is critical to prevent over-pressurization.

tension reduction Valves: Properly sized and often inspected force reduction valves protect the hopper from too much stress. The discharge within the relief valve really should be directed to a secure locale, including a collection tank.

Vacuum units: For selected programs, protecting a slight adverse pressure inside the hopper may help avert leaks. This can be attained utilizing a vacuum pump connected to the hopper's vent system.

Optimized Filling: very carefully managed filling treatments lower spills and splashing.

Splash Guards: Installing splash guards round the hopper's inlet points minimizes the risk of fluid escaping during filling.

Magnetic Quick Latch Lids: These protected lids stop accidental opening and decrease dust and liquid escapes.

Zero-Leakage Valves: Drip-free valves for draining are significant, Specially with hazardous materials.

Valve collection: superior quality ball valves or gate valves.

typical Inspection: Valves needs to be inspected on a regular basis for use and tear.

Leak Detection and Response Systems

Proactive checking and immediate response are important to reducing the effects of any leakage that does happen.

Sensor Integration: The strategic placement of sensors can offer early warning of leaks.

Liquid Detection Sensors: These sensors can detect the existence of liquid on the floor or around the hopper.

Gas Detectors: Some drilling muds include unstable factors, such as hydrogen sulfide (H2S). Gas detectors can notify staff into the presence of those gases, indicating a possible leak.

intelligent Alarms: Integrate sensors having a Handle technique for fast notifications.

Real Time knowledge: enables operators to right away react.

crisis techniques: establish a properly-outlined response strategy for leak scenarios.

computerized Shut Off Valves: automated shutoff valves that automatically shut on detection of a leak.

Containment System: Strategically positioned capture basins and drainage systems

upkeep and Cleaning tactics

schedule upkeep and appropriate cleaning are vital for avoiding leaks and prolonging the lifespan of the hopper.

swift Disconnects: Modular design permits rapidly disassembly.

cuts down destruction: Facilitates repairs with out detrimental surrounding parts

Self Cleaning Nozzles: automatic programs to dislodge hardened product.

higher tension Washers: built-in nozzles that use large strain to wash the inside of your hopper, reducing the need for guide cleaning and likely exposure to hazardous components.

Residual Liquid Management: assortment units to seize drips.

Sloped base: Facilitates comprehensive drainage.

Material Compatibility: A important to extensive-expression Integrity

The choice of supplies for that mud mixing hopper is significant to its lengthy-term efficiency and resistance to leaks. Drilling fluids might be really corrosive, as well as the hopper materials must be compatible with the specific chemical composition of the mud.

Corrosion Resistance: Matching resources to predicted chemical exposure.

Hastelloy and Stainless Steel: For remarkably corrosive fluids.

Coatings: protecting levels to boost chemical resistance.

Nano Ceramic Coating: helps prevent corrosion from acid mud.

Compatibility Charts: Providing in depth guides on Harmless product combos.

thorough Manuals: product compatibility guides to prevent mishaps.

dealing with Intense problems

Drilling environments are often characterized by extreme conditions, like very low temperatures, superior pressures, and vibration. The mud mixing hopper must be created to resist these circumstances with out leaking.

reduced Temperature Resilience: utilization of cold-resistant products.

specialised Seals: Seals need to continue to be versatile at Excessive temperatures.

Vibration Management: Absorbing shocks to protect seals.

Dampeners: To reduce strain on joints and seals

FEA Simulation: Simulation screening to assess pressure resistance.

making certain Structural Integrity: Finite factor Investigation to simulate and check structural components

Differentiating Solutions: From Reactive to Proactive

common approaches to leak prevention in mud mixing hoppers frequently count on reactive measures, for instance patching leaks because they come about. However, a far more proactive and strategic approach is necessary to minimize the dangers and fees related to leakage.

wise Leak Prevention Kits: Integrated systems for monitoring and control. These kits can include things like:

authentic-time sensors: supplying ongoing checking of essential parameters.

Automated shut-off valves: quickly isolating the hopper in the celebration of the leak.

Cloud-dependent platforms: Enabling distant checking and facts Assessment.

Industry Certifications: Compliance with specifications such as API 16C.

Adhering to expectations: assures which the devices continues to be tested and fulfills market finest techniques.

instruction and Education: Educating end users on best practices.

reducing leaks in mud mixing hoppers is just mud mixing hopper manufacturer not pretty much compliance; It is really about operational performance, environmental responsibility, and worker protection. By focusing on strong structural style and design, employing proactive operational strategies, leveraging leak detection technologies, and prioritizing right upkeep, drilling operators can substantially lessen the risks and expenditures affiliated with leakage. This proactive approach makes sure a safer, additional productive, and environmentally seem drilling operation. choosing the appropriate equipment from the respected mud mixing hopper manufacturer can be a critical decision that impacts every aspect of your drilling operation. When considering your next mud mixing hopper purchase, or analyzing your latest gear, understand that buying top quality, layout, and preventative steps interprets to significant very long-expression price savings and relief. quality Drilling is committed to giving solutions that lessen environmental impact and increase your operational performance.

Scott Baio Then & Now!

Scott Baio Then & Now! Jenna Von Oy Then & Now!

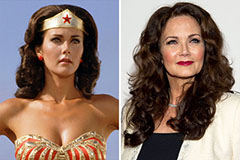

Jenna Von Oy Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!